Quality Assurance

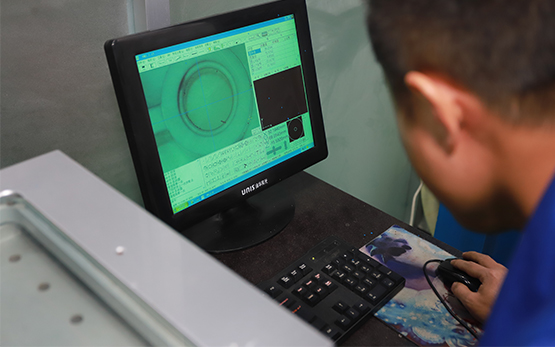

Plastics Measurement

As normal work flow, we make measurements for all the T1 parts and offer dimension reports to our customers. Our 3D Optical Video Measuring Machine with accuracy 3µm and measuring range 300*200*150mm helps a lot on these product measuring.

Steel Dimension Control

During the workpiece machining process, we inspect the critical inserts cavity/core/movements with Coordinate Measuring Machine in different stages. All the electrodes are measured as well before they go to EDM machine. This will avoid mistakes at the earlier stage and ensure the steel dimension precise and meet the highest standards of quality.

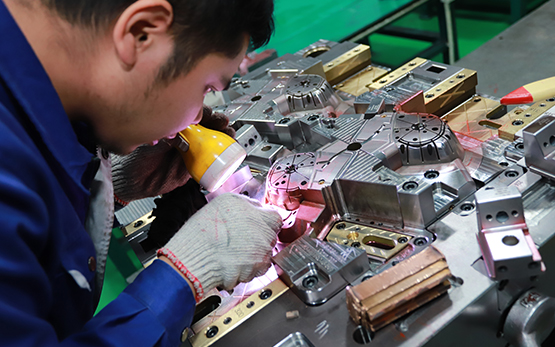

Molds Inspection

Our mold inspection process sets the bar very high for all molds before they are permitted to ship. After final part approval, the mold will undergo a 100% tear-down inspection. Each component is measured, hardness-tested, and recorded by our in-house QC inspectors. Some would be inspected by our customers if they are here. Only after going through this process and improving the defects, the mold will go to box.